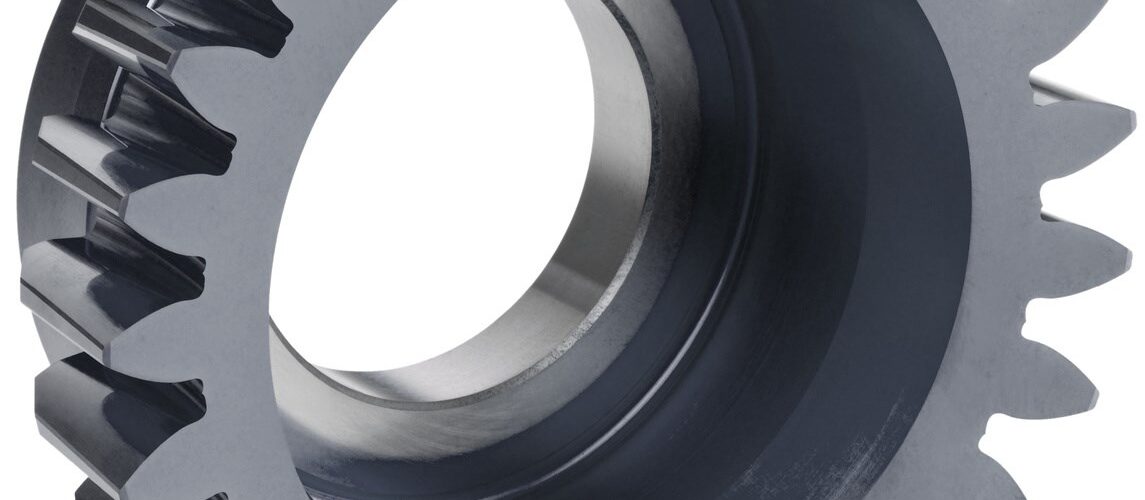

A stuff diagram is a vital method utilized in the assembling of cogwheels. One of the strategies for accomplishing device development is the utilization of cutters. These pinion wheels forming gears are to a great extent partitioned into four sorts of the plate, harp, shank, and helical cutters. The cutters are the cogwheels used to make the teeth. Stuff shaper works incredibly pleasantly to get surprising outcomes. The cutters are slanted to work in agreement with the wide assortment of veneers in the shaper. These make lessening more noteworthy viable. Stuff cutters are one of the decent techniques to deliver one’s stuff.

There are such forming machines helpful on the lookout. There are more than a couple of motivations behind instruments forming as well. These capacities are comprehensively utilized and forming cutters are urgent to acquire these applications. Maxwell Tools has kept up the ubiquity of one of the uncommon gear shaper cutters providers in India. Here are a few advantages of molding cutters-

• Suitable for mass assembling of pinion wheels- These forming cutters are awesome for delivering gears in a monstrous amount. This doesn’t infer that the idea of pinion wheels is sabotaged. Contrasted with any extraordinary cycle, the stuff shaping method takes substantially less time in making a scope of sorts of pinion wheels. With this component, the strategy of shaping the instruments will create a monstrous amount of cogwheels in a brisk time. The mass assembling of every medium and enormous measured pinion wheels will build the pay of the maker and thus will expand his benefit.

• Close resistance to equip cutting- The forming cutters are extremely right and special in the estimations while decreasing the cogwheels. The more the pinion wheels are exact, the more prominent is the interest of the pinion wheels. Quality is generally the ideal characteristic that a customer finds in the stuff. With shut resistance instruments cutting, the cogwheels created have the finish of supported veneer profile and the best strain point. The molding shaper presents the uncommon cogwheels.

• Large scope of pinion wheels can be fabricated- One of the central endowments of forming cutters is that a solitary structure shaper can create a gigantic scope of pinion wheels. Pinion wheels of unique tooth-wide assortment and estimation can be created by methods for the indistinguishable structure shaper. This saves the maker more noteworthy endeavors to buy uncommon cutters for unmistakable cogwheels. This is refined with whole exactness and makes the molding method generally appropriate to various procedures of cutting. It limits one’s benefit of looking for cutters and makes greater the reflectivity of work.

• Light on the pocket- The forming cutters are currently not steeply-estimated and work effectively at a negligible expense. Their cost of conservation is also substantially less than different cutters. This increase makes molding cutters the top-notch shaper the same number of top incredible cogwheels can be produced using the forming cutters at the indistinguishable time and ease.

Conclusion– With such countless advantages of instruments forming cutters, numerous people manage to assemble or giving of stuff molding cutters. The stuff shaping cutters providers should be picked admirably. Find more tool reviews on https://toolsanalyzer.com.

If one is anxious about the decision of stuff shaper for one’s business, one can examine the gifts of structure cutters ordered through producers. These advantages will clear the entirety of one’s questions and make one love this item for one’s cogwheels.

Shiksha Book is an online assistance platform providing simplified and affordable Career guidance to aspirants of different exams in India. Our rich content along with the student friendly online exam portal provides best suitable career choice experience to students.